Side Cutouts

Reach ready to launch at RAM Marina

Reach was hauled out in RAM Marina in the Rio Dulce, Guatemala, starting in mid-Oct 2023. Replacing the black cutouts around the side windows and ports was one of several major fiberglass projects on the list (others include filling the chine and stern extensions). It was also the only one that Mark decided to farm out to the yard. It was a tough job.

This area is recessed about 3/4” inch integral to the main hull. Early Dolphin catamarans had this area filled with plywood core (later Dolphins used foam). There are four fixed windows and four opening ports along each side.

The issue with ours was that there is no way to keep plywood sealed in this setting so over time it got saturated and rotting in some places.

A minor leak around an opening port was noticed, plus the wet wood “weeped” brown water down the sides of the boat.

So this was “on the list” for a redo. The plan was to remove all plywood core down to the hulls and replace this with nidacore.

One thing we would have liked to have done but couldn’t was replace the Lexan polycarbonate fixed windows as they are crazed by this stage. It wasn’t possible to source polycarbonate in Guatemala and the acrylic there is poor quality, so we reused the original windows. The opening Goiot portholes were still in great shape.

Saúl in the “fiberglass shop” under Reach

We chose RAM Marina based on our experience with them doing our Manta stern extension 10 years ago.

It was great working with Saúl again! He is such a hard worker and has a great sense of humor.

For this job, we also had the help of more of the RAM crew, Jason and Luis.

The toughest and most tedious part was removing the existing plywood core. I have a ton of photos (of course) documenting the process. Other Dolphin owners with similar issues will be interested to see how things look behind the paint, so I’ll lay out the steps below.

Remove plywood core

Remove ports and re-seal Lexan windows

Fit and glass nidacore cutouts

Fill and fair fiberglass

Replace ports and seal all windows

Add base coat of primer

Spray black paint

Re-install and seal opening ports

Repeat other side

Remove Plywood Core

As mentioned, the plywood core removal was the most laborious of the steps using multitool cuts and a chisel. After removed, the remnants were ground out down to smooth fiberglass.

Messy job!

Remove Ports and Re-Seal Lexan Windows

The opening Goiot ports were removed for the next portion of the work. The polycarbonate windows were “slab” windows with the shape given by the outer core.

All but two Lexan windows were able to come off and be resealed. Those windows would not come off with risk of damaging them (noting that we didn’t have a new source for replacement polycarbonate). So, these were re-sealed in-situ. All windows were re-sealed with 3M 4000 UV.

Side cutouts down to the hull

Fit and Glass Nidacore Cutouts

The shapes of the fixed windows were pre-traced onto a template. Nidacore was used to cover the Lexan windows at 1/4” and the intermediary spaces were fit using 1/2” Nidacore.

A top coat of chopped strand fiberglass mat made up the rest of the depth of the side cutouts.

Shaping nidacore

Fill and Fair Fiberglass

This is a “finesse” job, getting the surfaces fair and smooth. The paint will show any imperfections.

Resin with talc, as well as fairing compound is used first to fill the rough spots, followed by sanding from around 60 to 180 grit. Then another pass with fine fairing and touch-up is applied and sanded smooth with fine grit.

Fill and fair

Add Base Coat of Primer

Taping and covering all around the side cutouts is a job in itself. Reach was now ready for the sprayed on primer coat.

Several coats of primer were added with light fairing and sanding in between coats.

Primer coat

More fairing

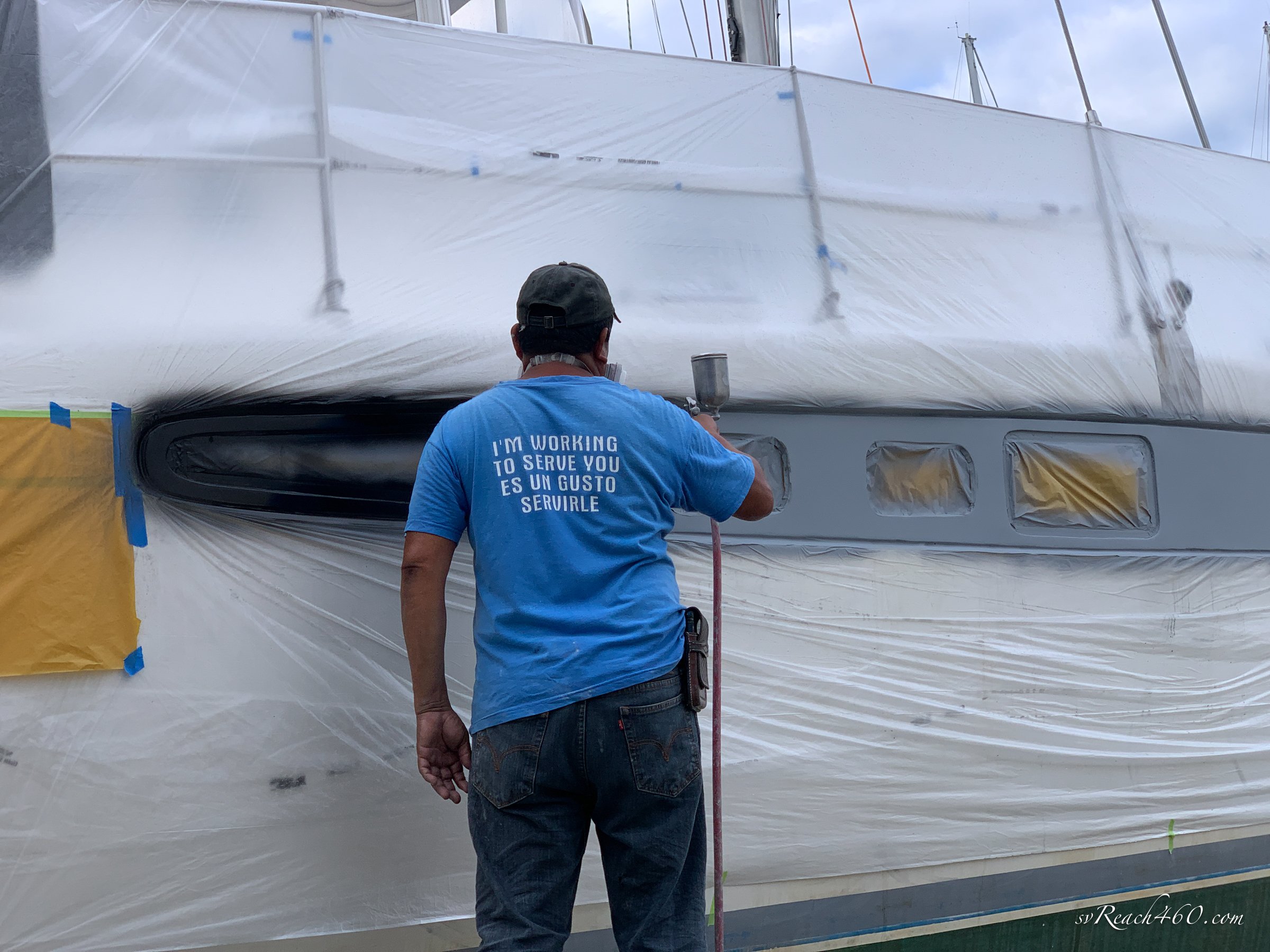

Spray Black Paint

A two-part black automotive paint was used to paint the cutouts. It was glossy, to be sanded down to the level of shine desired.

It was very shiny at first! We applied about 4-5 coats.

Spraying paint coat

Re-install and Seal Opening Ports

The Goiot ports were re-installed onto the new nidcore. Previously the frames were recessed 1/4” but we these were re-bedded flush with the nidacore for simplicity.

3M 4000UV black sealant was used for sealing the ports as well as all along the nidacore seams.

Port cutout

The Final Result

The final result

Repeat Other Side

This side went smoothly, learning the process from the first side. Saúl and crew made it look easy, even though it was still blazing hot.

I didn’t document this side as much as the first, but here is a quick recap of how it went.

Take #2

Taping for final sealant

We were very pleased with the outcome and glad to have this job finally checked off of the list!